Remalladora automática que se intégra en tus operaciones de acolchado, reduciendo el número de estaciones de trabajo y la manipulación del producto.

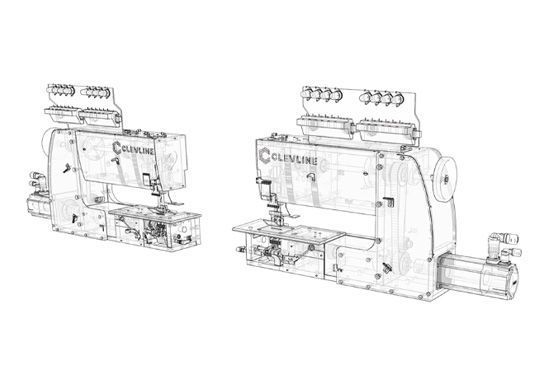

Máquina de corte y costura de paneles para colchón

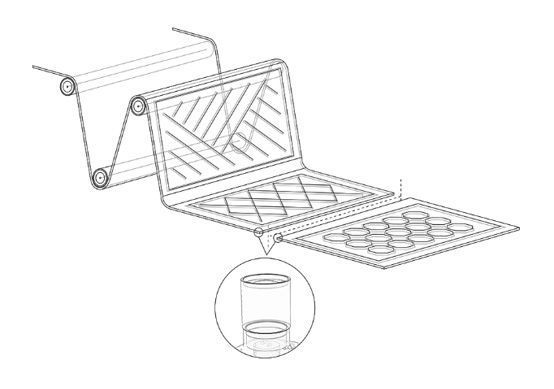

ClevPanel realiza dos procesos en uno: el corte y la costura del perímetro de la tapa se efectúan de forma simultánea, con lo cual se produce un importante ahorro de tiempo y de material, de manera que no será necesario dejar un margen en la tapa para el remallado.

Exactitud de panel

Alta precisión en las dimensiones de los paneles, al medir el avance del material acolchado en reposo mediante nuestro sistema de detección, situado en la mesa de evacuación.

Alta velocidad

Capacidad productiva de hasta 3,2 paneles/min, alcanzada mediante la sincronización entre los módulos de ClevPanel.

Cero desperdicio

Reducción de costes de materiales gracias al sistema de corte transversal.

Costura doble cadeneta

Técnica de costura que permite alcanzar altos niveles de producción y reducir los cambios de hilo, reduciendo interrupciones en la producción.

Espesor del material

El desarrollo exclusivo y adaptado de los cabezales aporta una alta flexibilidad en los espesores de material, entre 1 y 8cm.

Industria 4.0 ready

Una arquitectura electrónica avanzada nos permite cumplir con los requisitos de conectividad, modularidad y eficiencia energética requerida por la Industria 4.0.

Configura tu ClevPanel

01.

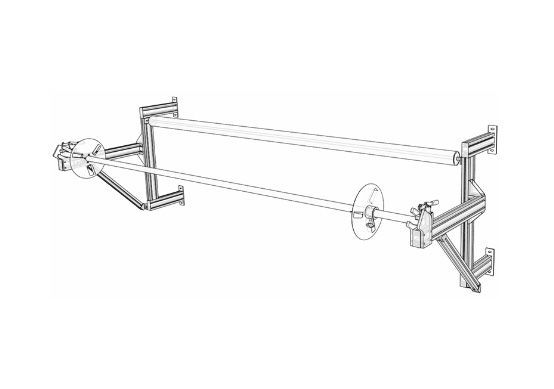

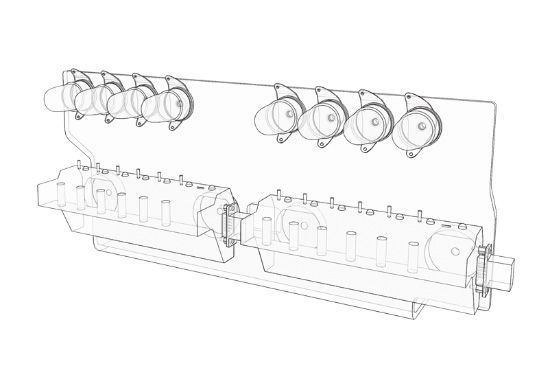

SOPORTE DE ROLLOS

02.

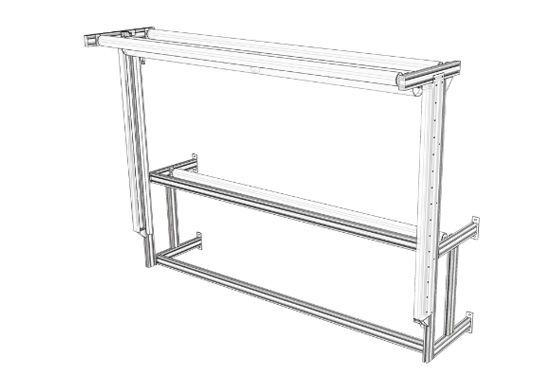

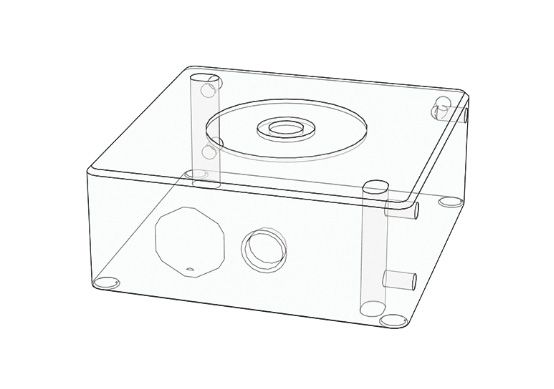

SMART COMPENSATOR

03.

PULLERS DE ENTRADA MOTORIZADOS

04.

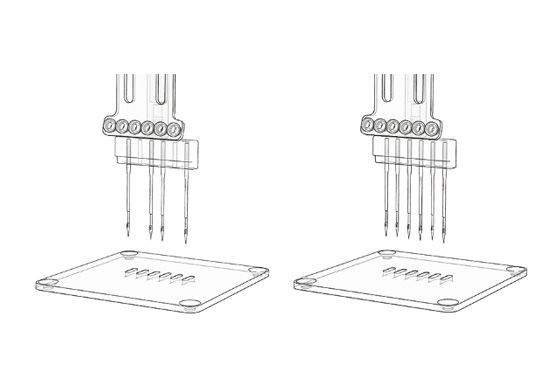

KIT DE 4 AGUJAS 1/4"

05.

DETECCIÓN DE ROTURA DE HILOS

06.

MOVIMIENTO LATERAL AUTOMÁTICO DE CABEZALES

07.

SISTEMA DE DETECCIÓN DE MARCA (EMPALME)

08.

CÁMARA DE RECONOCIMIENTO DE COSTURA

Automatiza las líneas de fabricación de paneles con diseños tapa-tapa mediante una marca de costura específica y reconocible, que se procesará como una orden de corte transversal, garantizando el centrado del dibujo.

09.

CLEVLINK (CLEVONE)

Comunica y sincroniza el flujo de trabajo entre la ClevPanel y la ClevOne, procesando una cola de producción para el conjunto de máquinas y adaptando automáticamente los cabezales laterales y transversal a la medida exacta, lo cual garantiza un perfecto centrado en los dibujos tapa-tapa.

10.

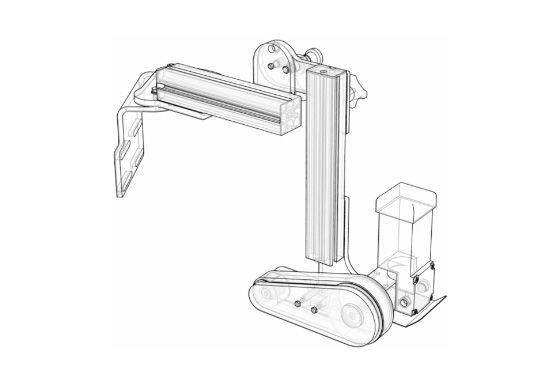

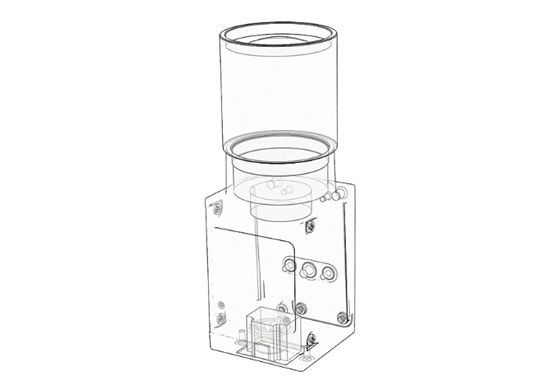

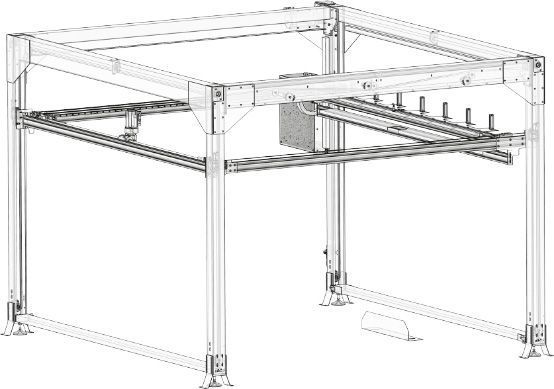

CLEVSTACKER

Máquina de apilado automático de paneles que contribuye a una mayor automatización de la línea de fabricación, totalmente integrada y sincronizada con nuestra ClevPanel, controlando ambas máquinas desde una misma pantalla de control.

Además, garantiza un aumento de la calidad del proceso productivo, evitando la manipulación de los paneles y eliminando tareas repetitivas, lo que libera al operario para realizar otros trabajos de mayor valor.

El objetivo del ClevStacker es apilar paneles hasta una altura de 2 metros, dotando a la línea de una autonomía de hasta 30 minutos sin intervención del operario en los cambios de pallet, permitiendo al operario la programación de lotes de apilado.

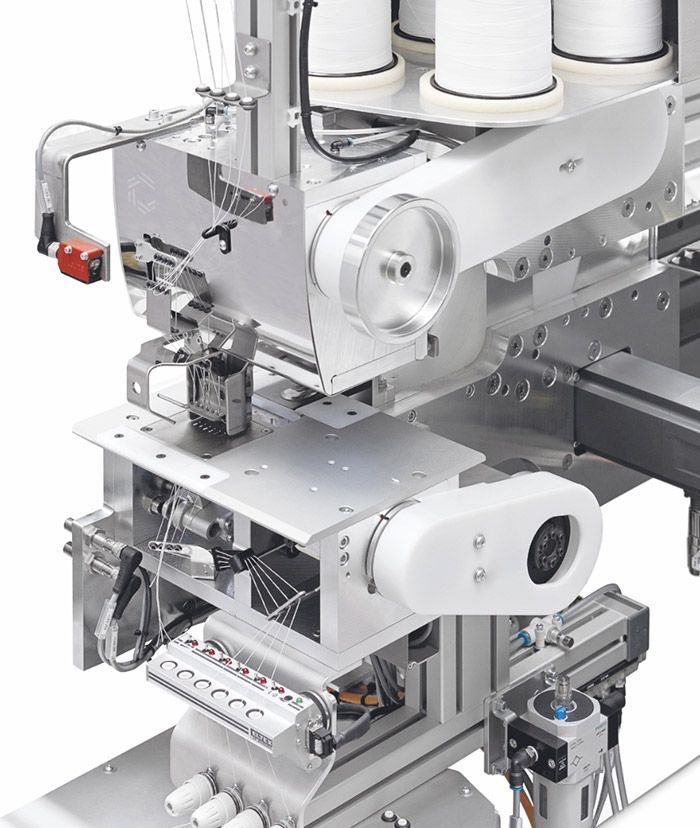

Cabezales de costura.

Diseñados por nuestro equipo exclusivamente para ClevPanel

Características de los cabezales de costura

01.

AFILADO DE CUCHILLAS AUTOMÁTICO Y PROGRAMABLE

Los ciclos de afilado del sistema de corte se gestionan a través de la pantalla HMI, manteniendo la calidad en el acabado del panel, sin afectar al tiempo de trabajo en la producción, y evitando riesgos para el operario.

02.

PROTECCIÓN EN EL BLOQUE DE COSTURA

La verificación del correcto posicionamiento de los elementos del bloque de costura previene posibles incidencias y daños en la mecánica de los cabezales. costes de mantenimiento.

03.

MECÁNICA INTERNA HOMOGÉNEA

El desarrollo de los cabezales se ha centrado en la homogeneidad de las piezas que componen su mecánica interna, facilitando el mantenimiento preventivo-correctivo y reduciendo el stock de piezas de repuestos.

04.

EVACUACIÓN DEL EXCESO DE MATERIAL ACOLCHADO

La evacuación del desperdicio lateral se orienta hacia el exterior del área de trabajo, evitando interrupciones en la producción y mejorando la seguridad del operario.

05.

ENGRASE AUTOMÁTICO Y PROGRAMABLE

El engrase de los cabezales es programable desde la pantalla HMI, reduciendo los costes de mantenimiento preventivo y alargando la vida útil de los elementos mecánicos.

06.

MOTORES SERVO-CONTROLADOS

La integración de estos motores eléctricos aporta un total control y precisión sobre la ejecución de una costura uniforme y de calidad.

Atributos de la máquina.

Propiedades.

01.

Trabajo en conexión con una máquina acolchadora

La conexión de la ClevPanel a una máquina de acolchar mejorará su eficiencia y producción.

02.

Sistema de control 4.0

Nuestro software permite a los usuarios introducir todos los parámetros necesarios en el proceso productivo diario: lotes de producción, controles funcionales.

03.

COMPONENTES DE PRIMERAS MARCAS

04.

SENSOR DETECTOR DE MATERIAL EN MESA DE EVACUACIÓN

Ficha técnica

Producción

| Tamaño panel (cm) | Tiempo panel | Paneles minuto | Metros minutos |

|---|---|---|---|

| 90×200 | 19 seg. | 3,2 | 2,9 |

| 105×200 | 19 seg. | 3,1 | 3,3 |

| 135×200 | 20 seg. | 3,0 | 4,0 |

| 150×200 | 21 seg. | 2,8 | 4,2 |

Datos eléctricos

Tensión entre fases: 400 Vac

Sección mínima: 4 mm

Potencia: 5 kW

Datos Mecánicos

ClevPanel: 5000 x 5560 x 2350 mm

ClevPanel + ClevStacker: 8500 x 5560 x 2350 mm

PESO:

ClevPanel: 2200 Kg

ClevPanel + ClevStacker: 3000 Kg

Datos Neumáticos

ClevPanel: 80 l/min

ClevPanel + ClevStacker: 100 l/min

Presión de trabajo estable: 6 bar

Datos Operativos

Los procesos de corte y costura de ClevPanel pueden funcionar simultáneamente o pueden desactivarse de forma independiente en cada uno de los cabezales de costura, sólo en modo corte.

Rango de anchos de los paneles a fabricar (sentido de avance): > 80, 90,… hasta 220 cm

· 1 cabezal longitudinal izquierdo de corte y costura configurado con 4 agujas.

· 1 cabezal longitudinal derecho de corte y costura configurado con 4 agujas.

· 1 cabezal transversal de corte y costura configurable de 4 a 6 agujas.

Noticias relacionadas

Sin categoría

¿Qué diferencia un proceso de producción normal de uno completamente automático?

Saber más

CLEVDYNAMIC

ClevDynamic: Descubre como dar el paso a la digitalización y sus múltiples beneficios.

Saber más

FERIAS

¡Visítanos en Interzum 2023! Descubra nuestras últimas innovaciones para la industria del colchón.

Saber más

FERIAS

Del 4 al 7 de Mayo estaremos presentes en la primera edición digital de INTERZUM

Saber más

CLEVONE

ClevLine más cerca que nunca

Saber más

CLEVONE

ClevLine: línea automatizada de fabricación de paneles acolchados

Saber más

CLEVONE

Vídeo ClevOne: acolchadora de alta precisión

Saber más

CLEVPANEL

Vídeo ClevPanel: máquina automática de corte y costura de paneles acolchados

Saber más

CLEVONE

Vídeo ClevOne: acolchadora de alta producción

Saber más

CLEVONE

Vídeo ClevOne: acolchadora de alta producción

Saber más