One line,

endless possibilities

Product Flexibility

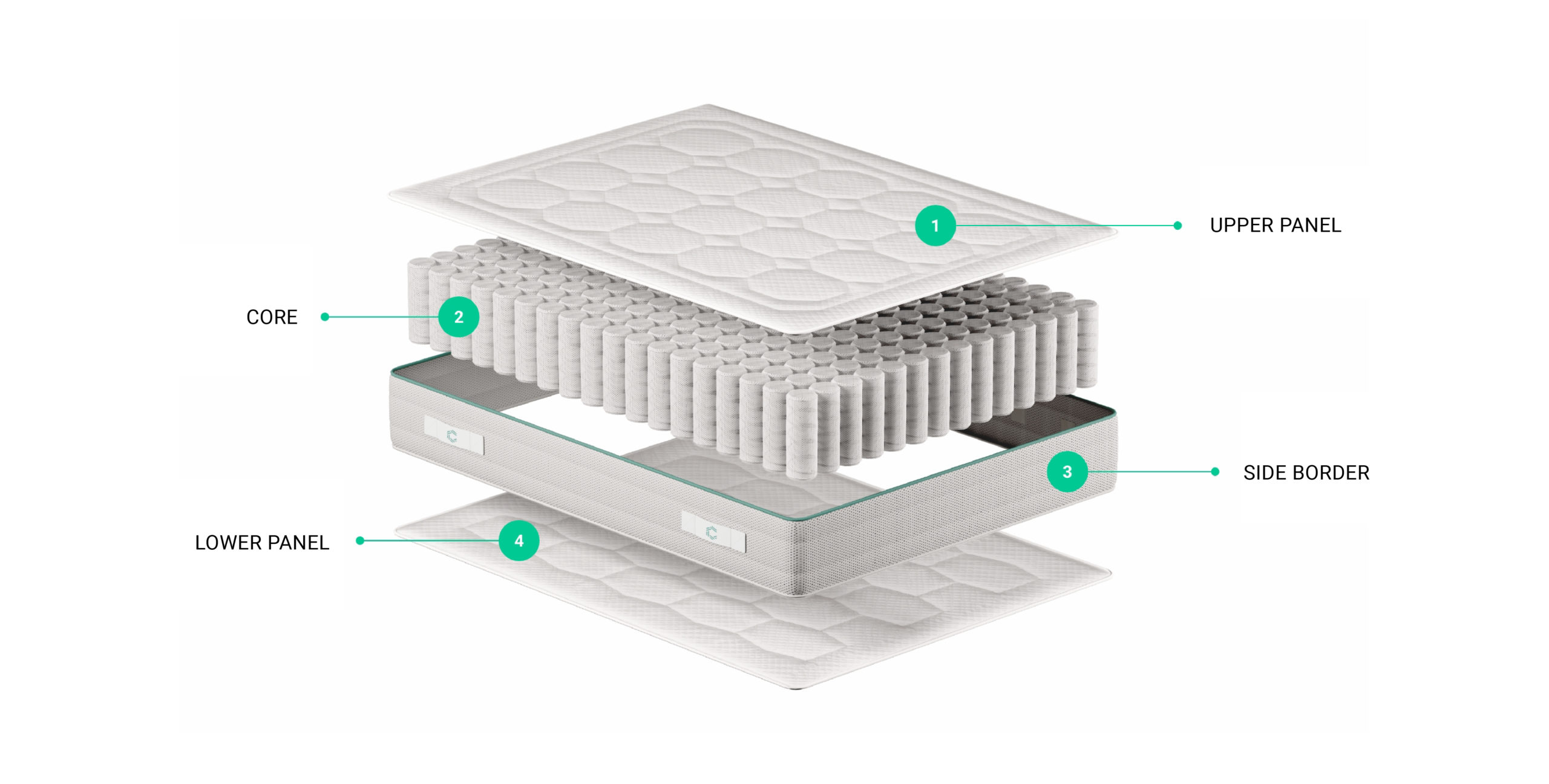

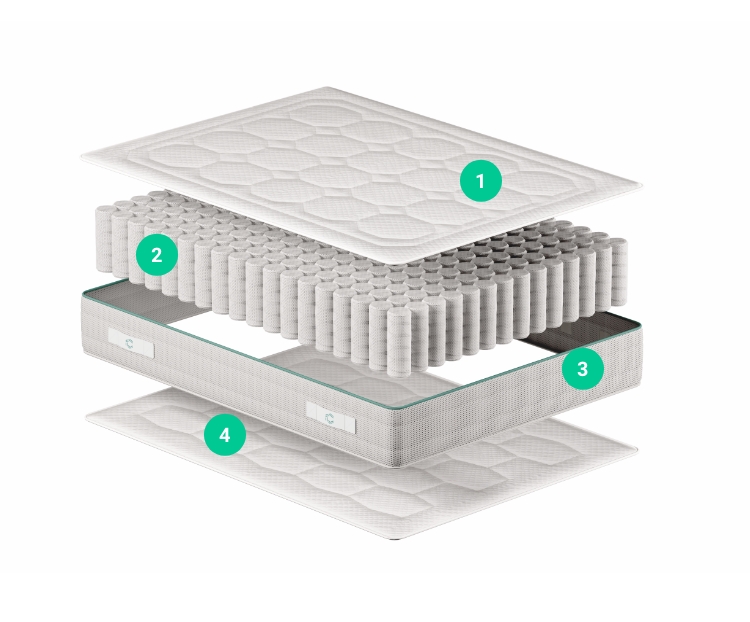

1Upper panel

2CORE

3SIDE BORDER

4LOWER PANEL

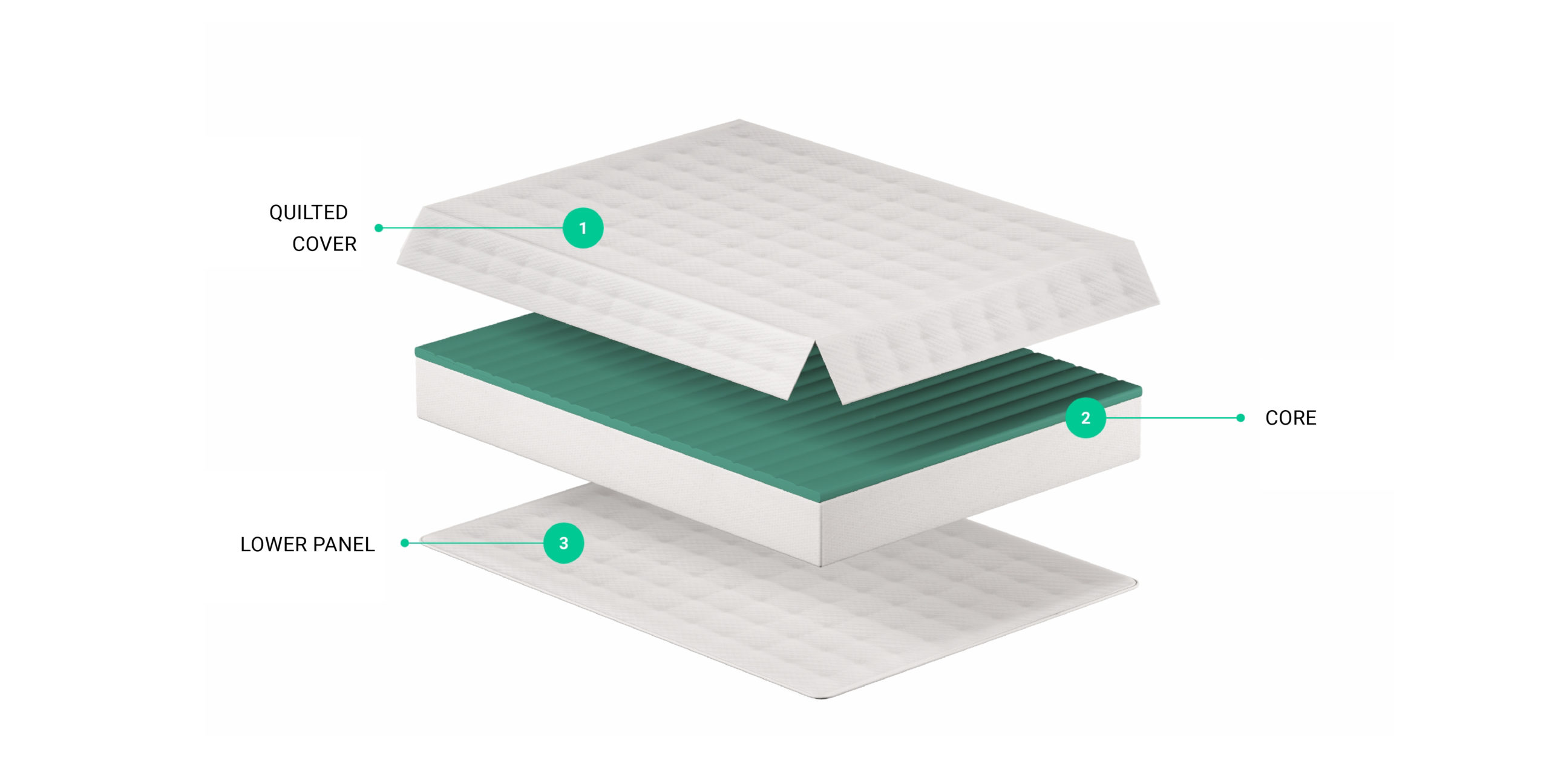

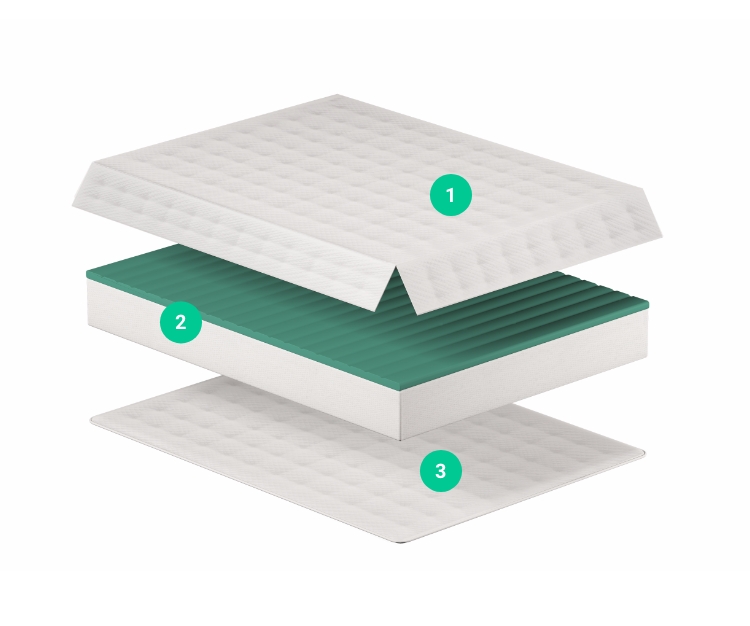

1QUILTED COVER

2CORE

3LOWER PANEL

Design Flexibility

FRAMED DESIGNS

Increase the productivity of your framed designs, traditonally linked to high-end products.

Centred Designs

Offers the possibility to work with centred designs with great freedom in the quilting appearance and the distance to the perimeter of the panel.

TRACK & JUMP designs

Total freedom in the quilted motives arrangement, without having a large impact on the machine's productivity.

continuous designs

The digital change of designs enables for a fast performance in the design changeover eliminating the needle distribution form the process.

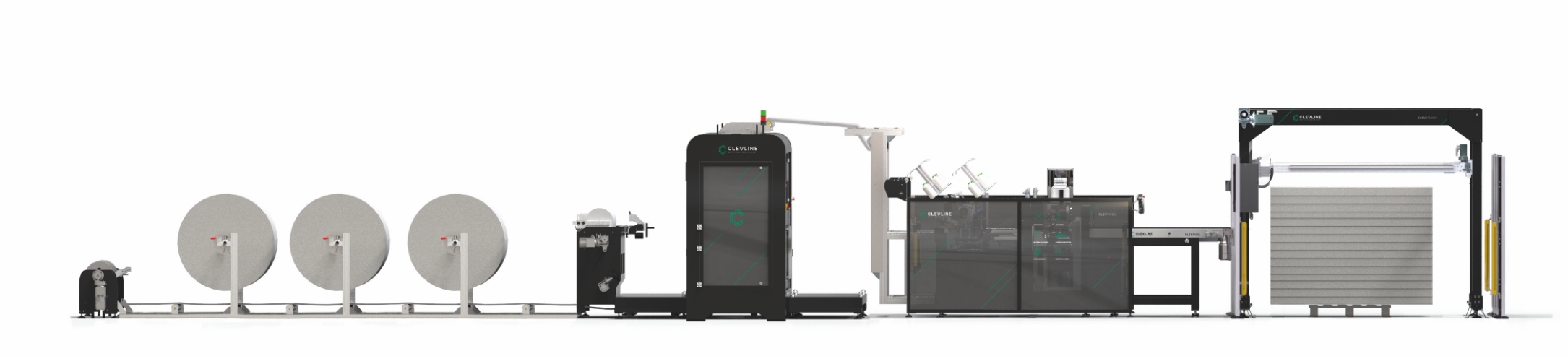

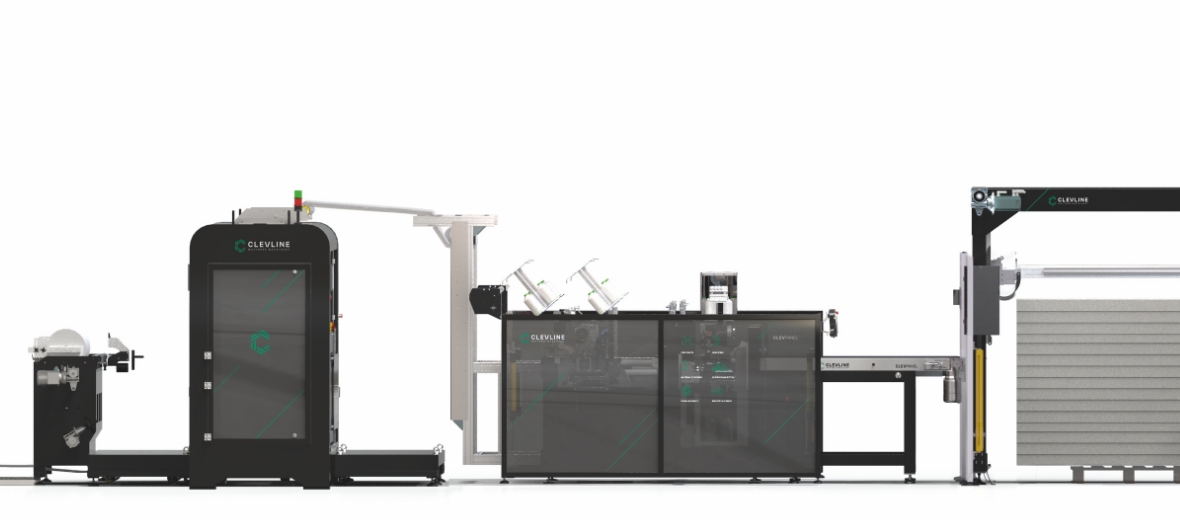

Line ClevLine

Our automated panel manufacturing line provides an improvement, control and efficiency of the production process, doubling production by reducing manufacturing times. Our development and integration of industry 4.0 allows us to increase flexibility and reduce time-to-market.

ClevDrawin’ is the software developed by our team to create designs and bring your ideas to life, with a full freedom for creativity. Its advanced and user-friendly functionalities enables you to create new designs in a timely manner.

ClevDrawin’ is the software developed by our team to create designs and bring your ideas to life, with a full freedom for creativity. Its advanced and user-friendly functionalities enables you to create new designs in a timely manner.

Unique quilting machine with a great scope for centred designs to work efficiently form continuous to frame designs; combining production leveles of multineedle processes with the accuracy of a double-headed single-needle machine. View product

Unique quilting machine with a great scope for centred designs to work efficiently form continuous to frame designs; combining production leveles of multineedle processes with the accuracy of a double-headed single-needle machine. View product Automatic hemming machine to complete quilted panel and cover’s perimeter with a high accuracy in the product’s dimensions. Integrates the cutting and sewing into the quilting process, reducing the number of working stations and easing the tape-edge process. View product

Automatic hemming machine to complete quilted panel and cover’s perimeter with a high accuracy in the product’s dimensions. Integrates the cutting and sewing into the quilting process, reducing the number of working stations and easing the tape-edge process. View product

Automatic stacking machine to achieve an extra level of autonomy in the process, avoiding product manipulation, reducing repetitive tasks and consequently freeing up the operators to focus tasks with a higher added value for the product.

View product

ClevLine Highlights

Product flexibility

Enlarge your product portfolio to satisfy all of your customer demands remaining competitive.

Access to new customers

Prepare your business to access to new customers and markets, with the possibility to adapt to new environments of intensive production and high quality demands.

Improve your lead-times

Improve your production capacity and efficiency of the quilting department, to achieve a more competitive lead-time.

Increase your production of frame designs

Reduce production times of your framed designs and achieve a higher production per square metre.

Optimise your resources

Automate your process to simplify tasks in the quilting department, avoiding non-productive transitions and reducing the number of working stations.

Industry 4.0 ready

Digitalise your quilting department with the Line ClevLine to improve your interaction with the machinery and reach a higher visibility over the process.

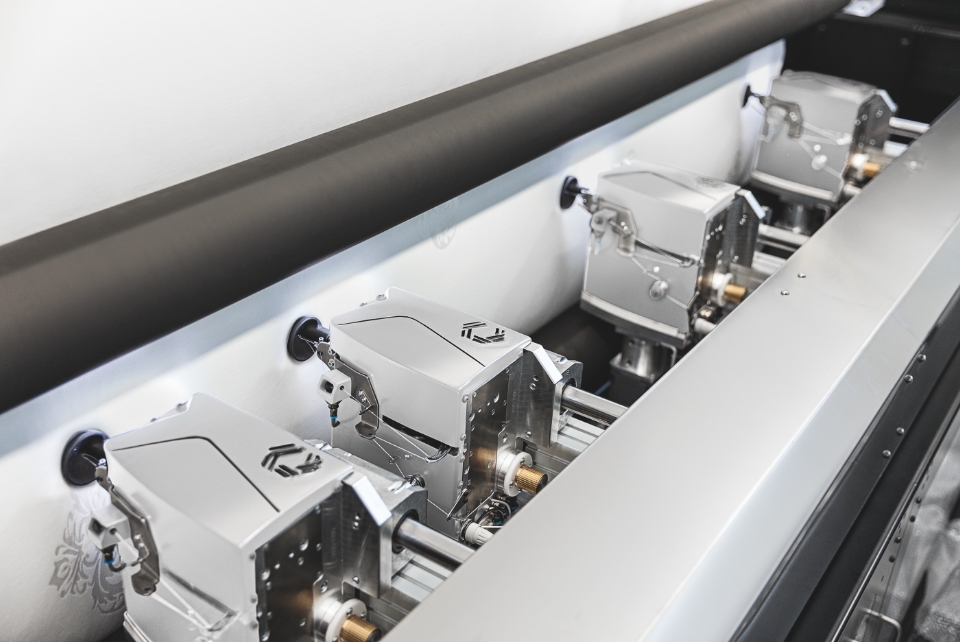

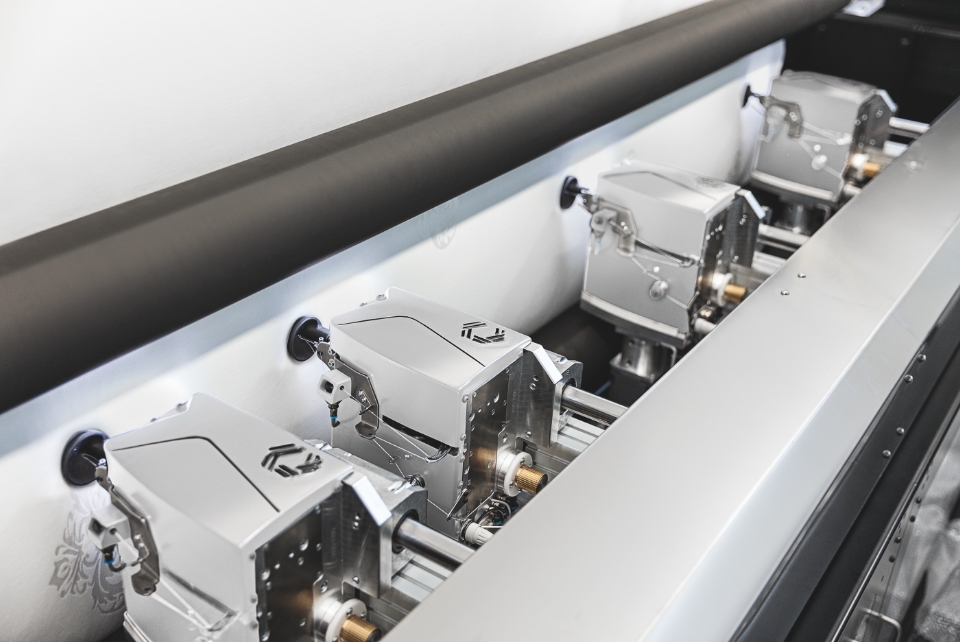

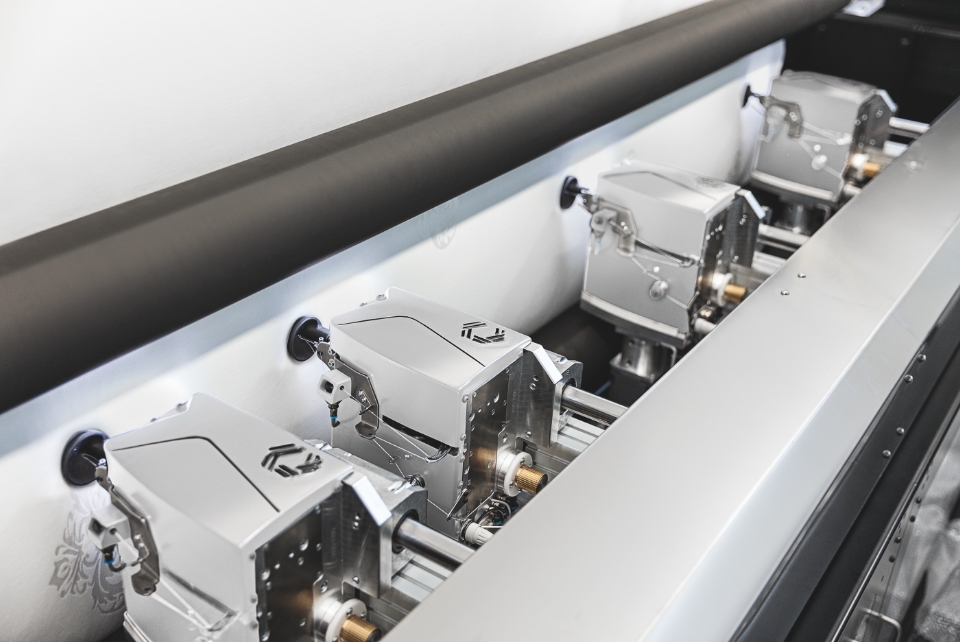

Our own Sewing-heads

Design to deliver a high quality sew

LOCKSTITCH

Provides an excellent accuracy and robustness to the sewing, improving the mattress appearance.

DOUBLE CHAINSTITCH

Assures a solid and constant sewing, reducing the number of interruptions and improving process autonomy.

LOCKSTITCH

Provides an excellent accuracy and robustness to the sewing, improving the mattress appearance.

DOUBLE CHAINSTITCH

Assures a solid and constant sewing, reducing the number of interruptions and improving process autonomy.

PUNTO ANODADO

Aporta una excelente precisión y robustez en la costura, mejorando la apariencia del colchón.

DOBLE CADENETA

Asegura una costura sólida y constante, con una reducción en el número de paros y mejora en la autonomía del proceso.

Technical Data

TECHINCAL DATA

ELECTRICAL DATA

Electrical Instalation: 3 p + tt + N

Phases Voltage: 400 Vac

Minimum Cable Section: 10 mm

Power Supply ClevOne: 15 kW

Power Supply ClevOne + ClevPanel: 20 kW

Power Supply ClevOne + ClevPanel + CLevStacker: 22 kW

MECHANICAL DATA

DIMENSIONS (L x W x H):

ClevOne: 1000 x 5800 x 2600 mm

ClevOne + ClevPanel: 15000 x 5800 x 2600 mm

ClevOne + ClevPanel + ClevStacker: 19200 x 5800 x 2600 mm

WEIGHT:

ClevOne: 7400 Kg

ClevOne + ClevPanel: 9600 Kg

ClevOne + ClevPanel + ClevStacker: 10400 Kg

PNEUMATIC DATA

AIR CONSUMPTION:

ClevOne: 150 l/min

ClevOne + ClevPanel: 230 l/min

ClevOne + ClevPanel + ClevStacker: 250 l/min

Air Presure: 6 bar

OPERATINAL DATA

INPUT MATERIAL:

· Input material width: max. 260 cm

· Working width: max. 240 cm

· Material thickness: 1-8 cm.

· Number of filing materials: max. 5 layers

More About ClevLine

CLEVONE

ClevLine ближе, чем когда-либо

Saber más

CLEVONE

ClevOne видео: высокоточный квилтер

Saber más

CLEVPANEL

ВИДЕО ClevPanel: АВТОМАТИЧЕСКАЯ РЕЗКА И ШВЕЙНАЯ МАШИНА ИЗДЕЛОЧНЫХ ПАНЕЛЕЙ

Saber más

CLEVONE

ВИДЕО CLEVONE: ВЫСОКИЙ ПРОИЗВОДСТВЕННЫЙ ПАДДЕР

Saber más

CLEVONE

Познакомьтесь с единственной стегальной машиной, отвечающей новым требованиям рынка

Saber más

CLEVPANEL

Посетите наш стенд на Interzum с 21 по 25 мая

Saber más